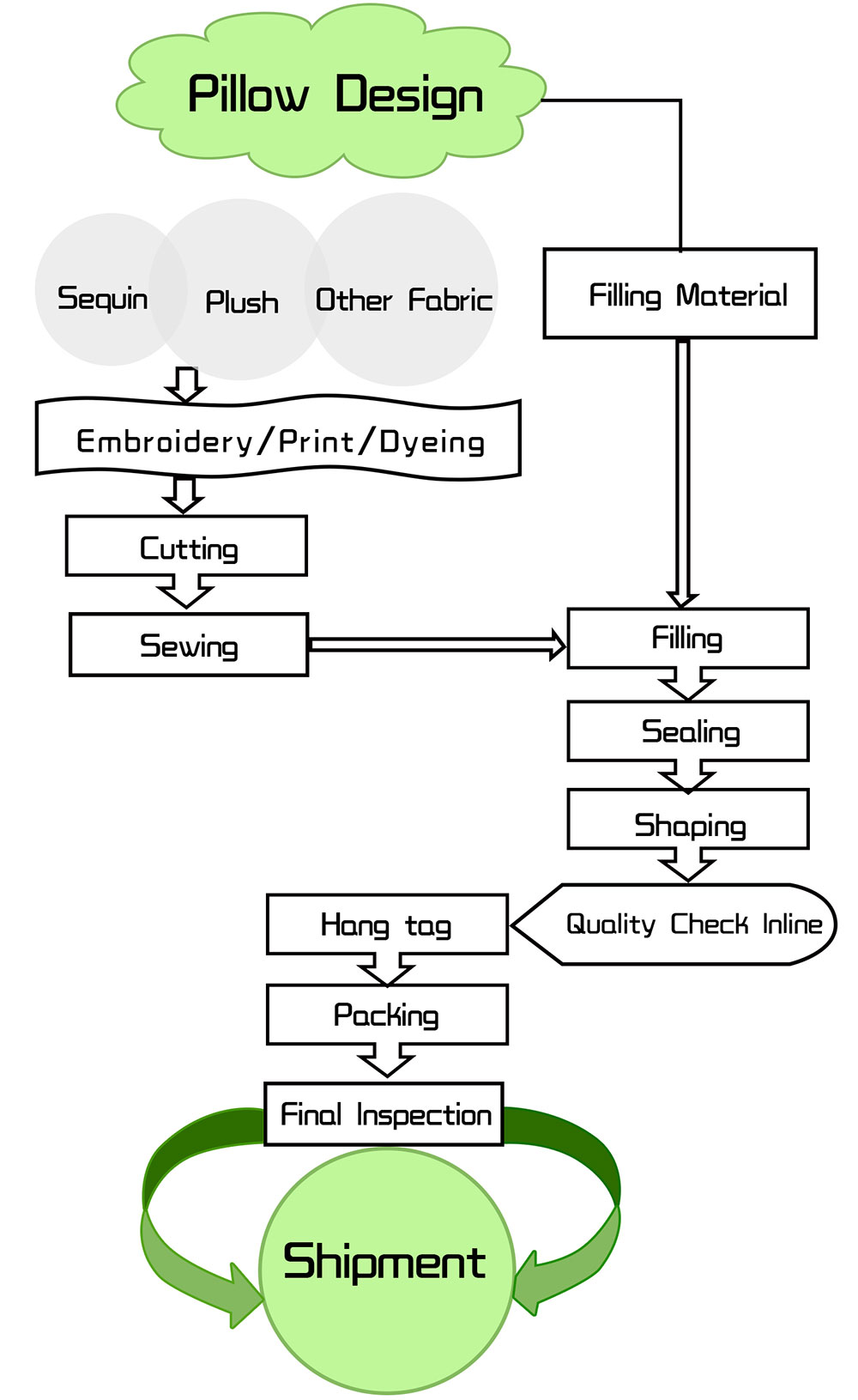

1. Design samples, select materials, and processes;

According to the customer’s artwork, or the artwork made by our designers ,as per customer’s requirements. We choose the materials that are non-toxic, environment-friendly, and guaranteed quality.

2. Plate printing and cutting

According to the design drawing, print the design draft in a 1:1 ratio. Sample room makes plate according to the drawing and cuts materials according to the plate.

3. Processing and production

Laminating the material, proceed those special process effects required by the customer, e.g. embroidery, ironing and bronzing, then stitch the parts together.

4. Stuff cotton or microbeads or memory foam etc. as per designing requirement.

According to sample production order, In addition, fill the appropriate amount of insert.

5. Sealing and shaping

Seal the mouth after filling. Then squeeze the sealed product, in order to make the shape perfect. And zip up the pillow if the insert with memory foam, or independent core.

6. Needle detection

Use needle detector test if there are broken needles left in the products. For those products passed testing, check if there is excessive thread ends, bad sewing and bad printing and embroidery, then fix if any defection.

7. Packing

The last install the product logo,and hanging card and so on, check the packaging method, packaging volume according to sample production order.